Refinery Products (Fuel & Gas)

Refinery Products (Fuel & Gas)

What is 'Oil refinery'?

Oil refining is a process by which crude oil is processed and transformed into usable petroleum products such as gasoline, diesel and other heating oils. The thick gooey substance extracted from the ground as unprocessed oil needs to be processed before different grades of oil can be extracted and used as fuels. The refining process is essentially the second phase of the process and is considered the downstream segment in the production process. The first phase i.e. extraction itself is considered the upstream segment.

Why it is necessary to refine crude oil?

Crude oils vary in colour and viscosity and are rich in hydrocarbons. Hydrocarbons are molecules of hydrogen and carbon that come in a variety of structures, from straight chains to branching chains to rings.

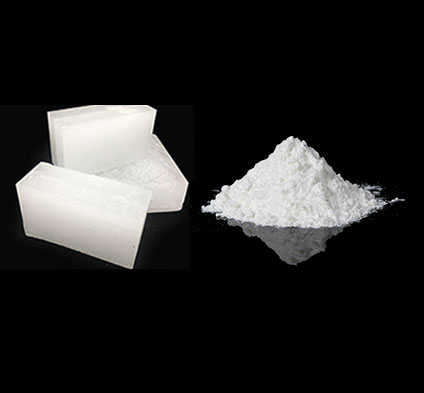

Hydrocarbons are particularly interesting as they store energy. Burning hydrocarbons release energy. A lot of products extracted from crude oils like gasoline, diesel and paraffin wax utilise this quality of hydrocarbons to release energy.

Also, hydrocarbons can be altered by processing them to make other forms of hydrocarbons. Molecules with long chains can be broken down to produce fuels and vice versa. These end products are often used in different applications- from fuels to aromatics to medicines and plastic.

To understand why it is necessary to refine crude oil, it is important to know the types of products that can be extracted from crude oil.

Petroleum gas, also commonly known as methane, ethane, propane, and butane, is used to heat, cook, and make plastic.

Naphtha or Ligroin can be further processed to make gasoline.

-

Gasoline

-

Kerosene

-

Diesel distillate or Gas oil

-

Lubricating oil

-

Heavy gas or Fuel oil

-

Residuals

-

How oil refineries work?

-

Raw unprocessed oil is called crude oil and it is a fossil fuel. Fossil fuels are fuels that are formed naturally by the decay of dead plants and animals over millions of years. On average, crude oil consists of 84% of carbon, 14% of hydrogen, 1 to 3% of sulphur and less than 1% of nitrogen, oxygen, metals and salts.

The main issue with crude oil is that many different kinds of hydrocarbons are all mixed in the sludge. Because of this, the crude oil is unusable unless the hydrocarbons are separated. The crude oil is passed through a process called ‘fractional distillation column’. This is the oldest and most common way to separate the components of crude oil. By the process of distillation, the hydrocarbons are separated as different hydrocarbons have different boiling points. As the crude oil is heated, different hydrocarbons are separated by their vaporisation temperatures and are called ‘fractions’. The quality of hydrocarbons depends on the type of chains they form in the molecule. Molecules having longer chain lengths have higher boiling temperatures and are used in a completely different way than the others.

Nowadays, a newer process is employed to treat crude oil. By this process, complex hydrocarbons are broken into simple ones so that yield per barrel of crude oil can be maximised. These processes are called-Cracking, where long and complex hydrocarbon chains are broken down into smaller and lighter ones such as LPG, gasoline, diesel etc.

Reforming, where the nature of hydrocarbons is changed to achieve desired physical properties.

Cracking can be achieved by different processes, namely - Thermal cracking- here intense heat is used to break down the heaviest hydrocarbon molecules that have emerged from the distillation process. The intense heat ‘cracks’ the molecules into smaller hydrocarbons, leaving a by-product that is almost pure carbon called coke. This process is employed on residual oil to extract fuel oil, diesel, gasoline and naphtha.

Hydrocracking- here fractions like gas oil, kerosene and naphtha are heated to 300-400C with hydrogen at high pressure in the presence of a catalyst. Trace impurities like sulphur, nitrogen and metals can be removed by this process.

Catalytic cracking- here residual oils or gas oil are broken down in the presence of a catalyst under intense heat and pressure conditions. Sometimes hydrogen is also added to improve the quality of the hydrocarbons. The end process gives higher grades of hydrocarbons but the cost is significantly higher.

Reforming is done when hydrocarbons with smaller chains are combined to make hydrocarbons with larger chains. ‘Catalytic reforming’ is used to change low weight naphtha to aromatics that are used in making chemicals and blended gasoline.

Platinum and platinum-rhenium mix is used as a catalyst. Another process called ‘Alkylation’ is used to rearrange the molecules of one fraction to produce another. Compounds with lower molecular weight like propylene and butylene are mixed with catalysts like hydrofluoric acid and sulphuric acid giving high octane hydrocarbons that are used to blend gasoline.

Oil refining services and safety

Oil refining is a downstream function as stated earlier but many companies invest heavily in both upstream and midstream functions. From extracting oil to selling it as a final product, an integrated approach is followed to maximise profit margins. The refining part of the business is price sensitive and demands heavy investment. The refinery plants occupy huge tracts of land and employ heavy pieces of machinery. When the prices of crude oil fluctuate, it hurts the refining industry. That's why many companies choose to follow end to end service.

The refining industry is also a dangerous place to work. Accidents happen to result in the loss of human lives. Invisible fumes often cause health hazards like asthma, cancer, birth defects, neurological damage, blood disorders etc. oil refineries take certain steps to mitigate some of the hazards by: - Collaborating with local emergency response and safety teams.

- Invest in safety drills and encourage open communication among workers.

- Ensure proper communication of work and responsibilities so that everybody knows their precise roles before commencing work.

- Maintaining constant housekeeping so that accidents are minimised.

- Applying labelling techniques to communicate information to the workers and colour coding materials so that they are easier to find.

- Conduct regular inspection and maintenance of machinery so that they perform without any accidents.

The oil refining industry has come a long way. From a time when it produced a single product, kerosene, to a time when multiple products are extracted, the industry has seen many shifts in these years. It has become the world's most stringently regulated manufacturing industry with a significant amount of resources being spent on reducing its impact on the environment. With over 77 million barrels of crude oil produced per day in 2021, the need for oil is going to stay to sustain the economies and the daily lives of people.

Related Pages

Contact Us

Email:

info@ranholding.com

Phone:

+90-5059999971